In the bustling, high-pressure environment of a commercial kitchen, every detail matters. From the quality of ingredients to the precision of cooking, excellence is paramount. Yet, one often-overlooked element can significantly impact safety, staff well-being, and overall operational efficiency: the flooring. Specifically, the strategic deployment of high-quality non-slip rubber kitchen mats. For businesses across the UK, adhering to stringent health and safety regulations isn't just a legal requirement; it's a commitment to protecting your most valuable assets – your staff and your reputation.

Commercial kitchens are inherently hazardous spaces. Spills, grease, dropped food, and constant movement create a breeding ground for slips, trips, and falls. Beyond immediate accidents, the relentless demands of standing for long hours on hard surfaces can lead to chronic fatigue, musculoskeletal issues, and reduced productivity. This comprehensive guide will explore why non-slip rubber kitchen mats are not merely an accessory but an indispensable investment for any serious UK commercial kitchen. We'll delve into their multifaceted benefits, the various types available, critical selection criteria, maintenance best practices, and even spotlight a highly effective product designed for professional culinary spaces.

Table of Contents

- Why Non-Slip Rubber Kitchen Mats Are Essential for UK Commercial Kitchens

- Types of Non-Slip Rubber Kitchen Mats for Every Need

- Key Features to Look for in a Commercial Kitchen Mat

- Installing and Maintaining Your Kitchen Mats for Longevity and Performance

- Spotlight: The Red Value Kitchen Mat – A Smart Choice for UK Kitchens

- Real-World Applications: Where Kitchen Mats Make the Biggest Difference

- Frequently Asked Questions

Why Non-Slip Rubber Kitchen Mats Are Essential for UK Commercial Kitchens

The decision to equip your kitchen with proper non-slip matting is a foundational one for safety and operational excellence. It addresses a range of challenges unique to the commercial culinary landscape.

Mitigating Slip and Fall Hazards

Slips, trips, and falls remain a leading cause of workplace injuries, and commercial kitchens are particularly vulnerable. The Health and Safety Executive (HSE) consistently highlights the prevalence of these incidents. Wet floors from spills, condensation, and cleaning routines, combined with grease and food debris, create treacherous surfaces. Non-slip rubber mats are engineered with superior traction, often featuring textured surfaces and drainage holes, to significantly increase friction between footwear and the floor. This drastically reduces the likelihood of accidents, protecting your staff and potentially saving your business from costly injury claims and lost productivity.

Combating Staff Fatigue and Improving Comfort

Chefs, cooks, and kitchen staff spend countless hours on their feet, often on unforgiving concrete or tiled floors. This continuous impact can lead to foot, leg, and back pain, known as 'standing fatigue'. Anti-fatigue kitchen mats are designed with ergonomic principles in mind, providing a cushioned barrier that encourages subtle muscle movement, improves blood circulation, and reduces pressure on joints. This translates directly into more comfortable, less fatigued staff who can maintain focus and productivity throughout long shifts. Investing in anti-fatigue properties demonstrates a commitment to employee well-being, fostering a positive work environment.

Ensuring Optimal Hygiene and Cleanliness

Hygiene is non-negotiable in any food preparation environment. Commercial kitchen mats, especially those with open-grid or drainage designs, play a crucial role in maintaining cleanliness. They effectively channel liquids and debris away from the standing surface, preventing pooling and creating a drier, safer work area. Furthermore, many rubber mats are easy to clean, resisting bacteria growth and allowing for thorough washing and sanitisation, essential for meeting rigorous food safety standards in the UK.

Protecting Subflooring and Equipment

Beyond human safety, quality mats offer protection for your kitchen's infrastructure. Dropped knives, heavy pots, or equipment can chip tiles, dent concrete, or damage expensive flooring. Rubber mats act as a protective barrier, absorbing impact and potentially extending the lifespan of your underlying floors. They can also prevent slight damage to dropped items, reducing replacement costs over time.

Compliance with UK Health and Safety Regulations

In the UK, employers have a legal duty under the Health and Safety at Work etc. Act 1974 to ensure, so far as is reasonably practicable, the health, safety, and welfare of their employees. This includes providing a safe working environment and taking measures to prevent slips and trips. Properly selected and maintained non-slip kitchen mats are a tangible demonstration of this commitment, helping businesses comply with HSE guidance and avoid potential penalties or legal action.

Types of Non-Slip Rubber Kitchen Mats for Every Need

The world of commercial kitchen mats is diverse, with specific designs tailored to different areas and operational demands. Understanding these variations is key to making the right choice for your establishment.

Grease-Resistant Nitrile Rubber Mats

For areas exposed to high levels of animal fats, oils, and greases – think fry stations or grill lines – standard rubber mats can degrade quickly. Nitrile rubber mats are specifically formulated to resist these harsh substances, offering superior durability and longevity in challenging environments. Their chemical resistance ensures they maintain structural integrity and non-slip properties even with daily exposure to aggressive cooking byproducts.

Drainage Mats

Where liquids are prevalent, drainage mats are indispensable. These mats feature an open-grid or patterned surface with strategically placed holes that allow spills, water, and food particles to fall through to the subfloor. This keeps the top surface relatively dry and clean, greatly reducing slip hazards. They are ideal for dishwashing stations, food preparation areas, and walk-in refrigerators where ice and water are common.

Anti-Fatigue Mats

While many commercial mats offer some degree of anti-fatigue properties, dedicated anti-fatigue mats are engineered primarily for ergonomic comfort. They typically feature thicker profiles and a resilient cushioning material that dissipates impact and stimulates micro-movements in the leg and foot muscles. These are best placed in static workstations where staff spend extended periods standing, such as prep lines, serving stations, or behind the bar.

Interlocking Tile Systems

For large or unusually shaped kitchen areas, interlocking rubber mat tiles offer unparalleled versatility. These modular systems allow you to cover vast spaces or create custom configurations around fixed equipment. If a single tile becomes damaged or excessively worn, it can be easily replaced without needing to replace the entire matting system, making them a cost-effective long-term solution.

General Purpose Mats

While not specialised for extreme grease or fatigue, general-purpose non-slip rubber mats still offer significant improvements in safety and comfort over bare floors. They are a good choice for less intense areas or where budget is a primary consideration, providing reliable slip resistance and a basic level of cushioning.

Key Features to Look for in a Commercial Kitchen Mat

Choosing the right commercial kitchen mat involves more than just picking a non-slip surface. A detailed understanding of key features ensures you select a product that perfectly matches your operational needs and UK safety standards.

Material Composition: Nitrile vs. Natural Rubber

- Nitrile Rubber: Highly resistant to oils, greases, and chemicals. Ideal for areas with heavy fat exposure (e.g., fryer stations, grill areas). More expensive but offers superior longevity in harsh conditions.

- Natural Rubber: Excellent elasticity and anti-fatigue properties. Good for general wet areas and dry environments. More susceptible to degradation from oils and greases, typically more cost-effective.

Many high-quality mats blend these materials to achieve a balance of resistance, durability, and comfort.

Slip Resistance Rating (R-Rating)

When selecting non-slip mats, particularly for the UK market, understanding slip resistance ratings is crucial. The most common standard is DIN 51130, which assigns an 'R-rating' from R9 (lowest slip resistance) to R13 (highest slip resistance) based on a ramp test with oil. For commercial kitchens, an R10, R11, or R12 rating is generally recommended, depending on the level of grease and moisture present. The higher the number, the greater the slip resistance.

Drainage Capabilities

The effectiveness of drainage is paramount in wet kitchen environments. Look for mats with sufficiently large and well-spaced drainage holes or a robust raised-pattern design that allows liquids and debris to flow beneath the mat. This prevents contaminants from sitting on the walking surface, maintaining a safer, drier area.

Anti-Fatigue Properties

Evaluate the mat's thickness and construction for its anti-fatigue benefits. Thicker mats with a cellular structure or air pockets tend to offer better cushioning. Consider the areas where staff stand for prolonged periods and prioritise mats specifically designed to reduce strain and improve comfort in those zones.

Bevelled Edges and Safety Ramps

Trip hazards can be just as dangerous as slip hazards. Mats with bevelled (sloped) edges or integrated safety ramps significantly reduce the risk of tripping over the mat's perimeter. This feature also facilitates easy trolley and cart access, making movement around the kitchen smoother and safer.

Ease of Cleaning and Sanitisation

A mat's design should facilitate quick and thorough cleaning. Mats that can be easily hosed down, scrubbed, or even run through commercial dishwashers are ideal. Ensure the material is resistant to common kitchen cleaning chemicals to maintain its integrity and hygienic properties over time.

Installing and Maintaining Your Kitchen Mats for Longevity and Performance

Even the highest quality non-slip rubber kitchen mats will only perform optimally if correctly installed and regularly maintained. A proactive approach to care ensures maximum safety, hygiene, and extends the lifespan of your investment.

Proper Placement and Installation

Strategic placement is critical. Mats should be positioned in high-traffic areas, zones prone to spills (e.g., around sinks, fryers, dishwashing stations), and at workstations where staff stand for extended periods. Ensure mats lie completely flat on the floor to prevent trip hazards. If using interlocking tiles, ensure they are securely connected and cover the desired area seamlessly. Avoid placing mats in areas where they might impede door swings or create uneven transitions that could cause accidents.

Daily Cleaning Regimen

Commercial kitchens require a rigorous daily cleaning schedule, and mats are an integral part of this. At the end of each shift or day:

- Sweep/Scrape: Remove any solid food debris from the surface of the mat.

- Hose Down: If possible, lift the mats and hose down both the mat and the floor beneath it with hot water, using a mild detergent specifically formulated for kitchen use.

- Scrub: Use a stiff-bristled brush to agitate any remaining grease or grime.

- Rinse Thoroughly: Ensure all soap residue is rinsed away to prevent slippery surfaces.

- Allow to Dry: Hang mats to air dry or stand them upright to allow proper airflow. Ensure both the mat and the floor underneath are dry before repositioning the mat.

Deep Cleaning Practices

Beyond daily cleaning, scheduled deep cleans are essential, typically weekly or bi-weekly depending on kitchen volume and type of cuisine. For heavy-duty grease build-up, commercial degreasers may be necessary. Some industrial rubber mats are durable enough to withstand pressure washing, which can be highly effective for embedded grime. Always check the manufacturer's recommendations for deep cleaning to avoid damaging the mat material.

Inspection and Replacement

Regularly inspect your mats for signs of wear and tear. Look for:

- Cracks or Tears: These can harbour bacteria and reduce the mat's structural integrity.

- Degraded Edges: Frayed or worn edges can become trip hazards.

- Loss of Non-Slip Texture: If the surface texture appears smooth or less grippy, its slip resistance may be compromised.

- Flattened Areas: For anti-fatigue mats, significant flattening indicates a loss of cushioning properties.

Replacing worn-out mats promptly is crucial for maintaining safety and hygiene standards. A proactive replacement strategy is far more cost-effective than dealing with the aftermath of an injury caused by a degraded mat.

Spotlight: The Red Value Kitchen Mat – A Smart Choice for UK Kitchens

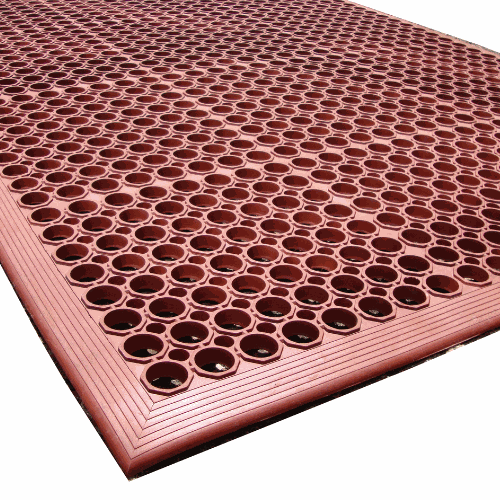

When selecting an effective and economical matting solution for your professional kitchen, the Red Value Kitchen Mat stands out as a reliable choice, perfectly balancing performance and affordability. Designed with the demanding UK catering environment in mind, this mat delivers on essential safety and hygiene requirements.

Red Value Kitchen Mat

Price: £55.00

This durable mat offers excellent non-slip properties, crucial for preventing accidents in busy kitchen areas. Its robust rubber construction is designed to withstand the daily rigours of commercial use, providing a safe and stable footing for staff. The integrated drainage holes efficiently channel away spills and debris, keeping the surface clear and contributing to a cleaner, more hygienic workspace. Easy to clean and maintain, the Red Value Kitchen Mat is an intelligent, cost-effective investment for enhancing safety and operational efficiency in any UK commercial kitchen.

View Product DetailsWith its vibrant red colour, it also serves as a clear visual cue for safety zones. Discover more about how this mat can benefit your operations by visiting its product page at Mats4U.co.uk.

Real-World Applications: Where Kitchen Mats Make the Biggest Difference

The strategic placement of non-slip rubber kitchen mats can transform the safety and efficiency of different kitchen zones.

Front-of-House vs. Back-of-House

While this article focuses primarily on commercial kitchens (back-of-house), it's worth noting that front-of-house areas, such as server stations, bar areas, and even reception desks in restaurants, can also benefit from specific matting solutions. These might prioritise aesthetics alongside anti-fatigue properties. However, for the high-risk, high-volume environment of the actual kitchen, the focus is squarely on heavy-duty, performance-driven mats.

Specific Zones: Prep, Cookline, Dishwash, Bar Areas

- Preparation Areas: Here, drainage mats are vital. Chopping vegetables, washing produce, and preparing ingredients often lead to water, food scraps, and drips. Mats with efficient drainage keep the surface dry and minimise slip risks.

- Cookline/Fryer Stations: This is where grease-resistant nitrile rubber mats shine. The intense heat and constant splashing of oils and fats demand a material that will not degrade or become slippery under these conditions. Anti-fatigue properties are also highly beneficial for chefs working long shifts over hot surfaces.

- Dishwashing Stations: Wet, soapy floors are a constant challenge. Heavy-duty drainage mats are essential here to manage water overflow and ensure a stable standing surface for staff loading and unloading dishwashers.

- Bar Areas: While less intense than a main cookline, bar areas still contend with spills from drinks, ice, and broken glass. Smaller, often thinner, non-slip mats can provide crucial traction and some anti-fatigue benefits for bartenders.

Mobile Catering and Food Trucks

The compact and often dynamic nature of mobile catering units and food trucks presents unique challenges. Mats for these environments need to be robust, easy to clean, and potentially easier to roll up and store. Grease resistance and drainage remain critical, as these spaces are also prone to spills and debris. Lighter-weight, interlocking tile systems can offer flexibility for custom layouts in these confined spaces.

Frequently Asked Questions

Q1: How often should commercial kitchen mats be cleaned?

A1: Commercial kitchen mats should be cleaned daily to maintain optimal hygiene and slip resistance. For heavy-use kitchens, more frequent spot cleaning throughout the day may be necessary. Deep cleaning should be performed weekly or bi-weekly, depending on usage and grease build-up.

Q2: Are all rubber mats suitable for kitchens with grease and oil?

A2: No, not all rubber mats are suitable for areas with heavy grease and oil exposure. Natural rubber mats can degrade and lose their integrity when exposed to fats and oils. For these areas, it is crucial to use mats made from nitrile rubber or a nitrile blend, as these materials are specifically formulated to resist grease and chemicals.

Q3: What's the difference between anti-fatigue and drainage mats?

A3: Anti-fatigue mats are primarily designed to provide cushioning and reduce strain on staff who stand for long periods, focusing on ergonomic comfort. Drainage mats, on the other hand, are designed with holes or patterns to allow liquids and debris to pass through, keeping the standing surface dry and preventing slips. Many modern commercial kitchen mats offer a combination of both anti-fatigue and drainage features.

Q4: Can non-slip mats be cut to size?

A4: Some non-slip mats, particularly modular interlocking tile systems or those made from a solid, uniform rubber, can often be cut to size using a utility knife to fit specific areas or around equipment. However, always check the product specifications and manufacturer's instructions before attempting to cut a mat, as some designs may not be suitable for modification.

Q5: How do I know when it's time to replace my kitchen mats?

A5: It's time to replace your kitchen mats when you observe significant signs of wear and tear, such as cracks, tears, brittle or hardened material, loss of textured non-slip surface, or substantial flattening (for anti-fatigue mats). Degraded edges that curl or fray also indicate a need for replacement, as they can become trip hazards. Regular inspection is key to proactive replacement.

Q6: Do non-slip mats comply with UK health and safety standards?

A6: High-quality non-slip mats contribute significantly to compliance with UK health and safety standards, particularly those relating to preventing slips, trips, and falls in the workplace. While there isn't one single 'mat standard,' using mats with appropriate R-ratings and maintaining them properly demonstrates an employer's commitment to providing a safe working environment, aligning with HSE guidelines.

Q7: Are kitchen mats environmentally friendly?

A7: The environmental friendliness of kitchen mats varies by material and manufacturing process. Many modern rubber mats are made from recycled materials or are themselves recyclable at the end of their lifespan. Some manufacturers also focus on sustainable production practices. Look for products that highlight their environmental credentials if this is a key concern for your business.

Conclusion

The demanding environment of a commercial kitchen necessitates robust solutions that prioritise safety, hygiene, and staff well-being. Investing in high-quality non-slip rubber kitchen mats is a non-negotiable step towards achieving these goals. From mitigating dangerous slip and fall incidents to alleviating staff fatigue and ensuring impeccable cleanliness, these mats are silent guardians of your kitchen's efficiency and your team's health.

By understanding the different types of mats, recognising key features like grease resistance and drainage capabilities, and committing to proper maintenance, UK commercial kitchens can create a safer, more productive, and more compliant workspace. Explore the comprehensive range of matting solutions available at Mats4U to find the perfect fit for your specific needs, ensuring your kitchen operates at its peak performance while keeping everyone safe.

Stay connected and follow us for more insights and product updates: